Robot Linear Track Designed for Long-Distance Linear Travel

Product Overview

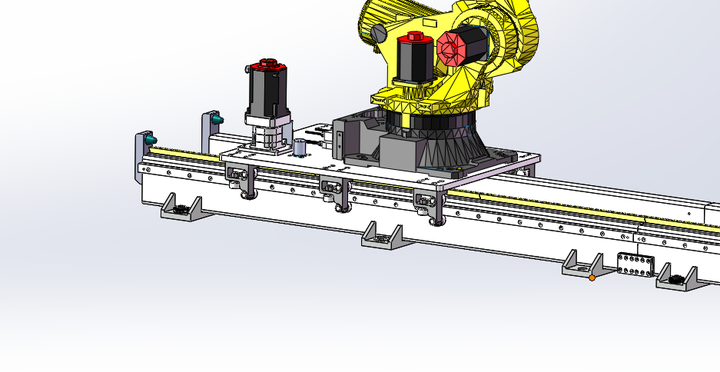

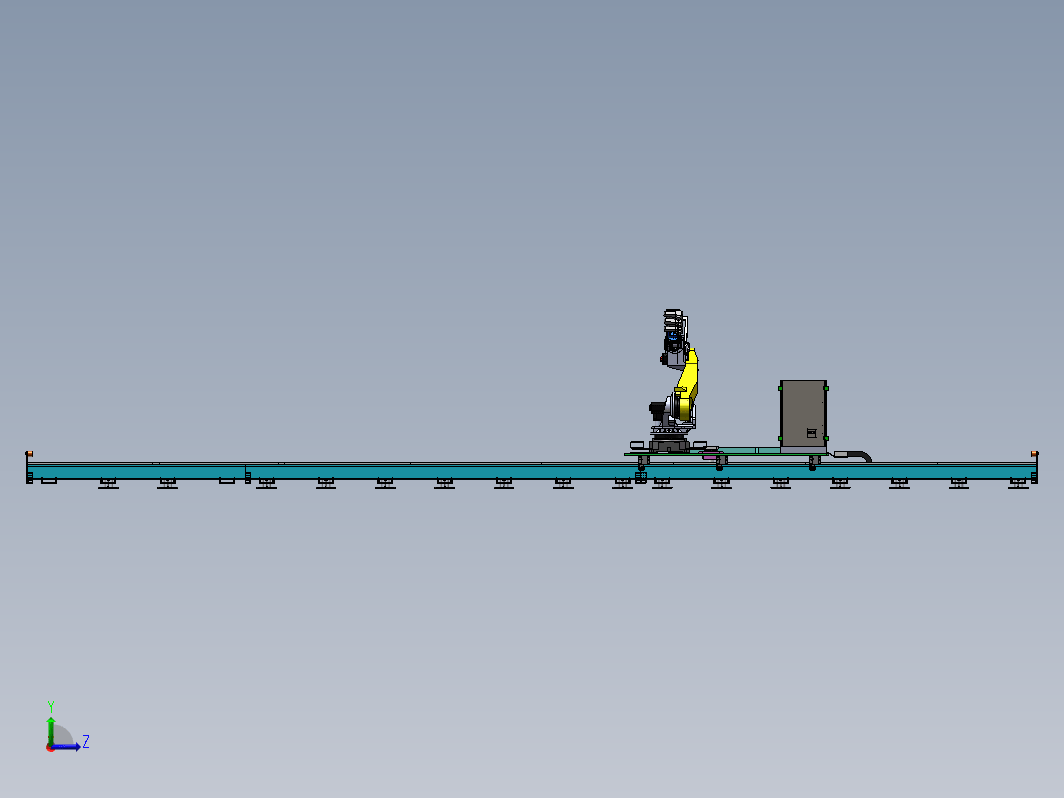

The medium-duty robot travel rail is a high-precision linear motion system designed specifically for welding automation applications. By enabling robots to move smoothly and accurately along the X-axis, this robot travel rail for welding significantly extends the working range of welding robots and improves productivity in automated welding lines.

Driven by a servo motor and precision rack-and-pinion transmission, the system delivers stable motion, high positioning accuracy, and reliable performance under medium to heavy loads, making it an ideal welding robot track for industrial automation environments.

Key Features

Medium-duty robot travel rail designed for welding automation

Servo-driven linear motion system with high precision

Repeat positioning accuracy up to ±0.10 mm

Precision rack and pinion robot travel rail with helical gears

High traveling speed suitable for automated welding lines

Modular design for flexible length configuration

Automatic lubrication system for reduced maintenance

Semi-enclosed protective structure for harsh welding environments

Technical Specifications

| Item | Specification |

| Product Type | Single-Axis Servo Robot Travel Rail |

| Control Axis | X-axis |

| Drive System | AC Servo Motor with Planetary Gearbox |

| Gearbox Ratio | i = 20 |

| Transmission Type | Helical Gear Rack Drive |

| Guiding System | Linear Guide Rails with Sliding Blocks |

| Installation Type | Ground-Mounted Installation |

| Maximum Travel Speed | ≤ 40,000 mm/min |

| Repeatability Accuracy | ±0.10 mm |

| Effective Stroke | Rail Length minus 1,400 mm |

| Maximum Total Load | ≤ 3,000 kg |

| Maximum Robot Payload | ≤ 300 kg |

| Lubrication System | Automatic Lubrication |

| Protective Structure | Semi-Enclosed Sheet Metal Cover |

| Surface Treatment | Powder-Coated Finish |

| Typical Applications | Welding and Material Handling Automation |

This linear motion system for welding automation ensures smooth robot movement and consistent welding quality across long working distances.

Structural Design and Reliability

The medium-duty robot travel rail features a semi-enclosed modular structure manufactured from high-quality steel profiles and plates. Through professional heat treatment and precision machining, the system achieves excellent rigidity, long-term stability, and durability under continuous industrial operation.

An integrated automatic lubrication system periodically lubricates the guide rails and rack-and-pinion components, reducing wear and extending service life. Robust sheet-metal protective covers with powder-coated surfaces protect the robot linear axis from welding spatter and dust while maintaining a clean industrial appearance.

Typical Applications

This high-precision robot travel rail for welding automation is widely used in:

Automated welding production lines

Welding robot travel systems and tracks

Steel structure and construction machinery welding

Robotic material handling and loading/unloading stations

Multi-station welding automation systems

By integrating a medium-duty robot travel rail, manufacturers can improve production flexibility, extend robot reach, and increase overall automation efficiency.

Why Choose This Medium-Duty Robot Travel Rail?

Optimized for welding automation equipment

High precision and stable servo-driven motion

Reliable performance under medium-duty industrial loads

Flexible modular configuration for customized layouts

Low maintenance cost and long service life

Conclusion

The Medium-Duty Robot Travel Rail with High Precision for Welding Automation is a reliable and efficient solution for extending robot working range in modern welding automation systems. With its servo-driven linear motion, robust structure, and precise positioning performance, it serves as a key component in high-quality automated welding production lines.

Contact us today to discuss your welding automation requirements and find the right robot travel rail solution for your application.